-

Home

- About Liduo

- Product Center

- RV lithium battery

- Forklift lithium battery

- Wall mounted lithium battery

- Golf cart lithium battery

- Server rack battery

- lithium iron phosphate battery

- Solution

-

Portable battery

-

Power battery

-

Energy storage battery

-

Server battery

-

Special batteries

-

Household energy storage

- OEM Services

- R&D

- News

Information center

Information centerThe production of AGV/RGV lithium battery is introduced

2025-03-21With the continuous improvement of the level of industrial automation, automatic guided vehicles (AGV) and rail guided vehicles (RGV) are more and more widely used in modern manufacturing. As the core power source of these intelligent vehicles, the performance of lithium batteries directly affects the operating efficiency and reliability of vehicles. This article will introduce the production process of AGV/RGV lithium battery in detail

1. Raw material preparation

The main raw materials of lithium batteries include positive electrode materials, negative electrode materials, membranes, electrolytes and shell materials. Before the production starts, these raw materials need to be strictly inspected and screened to ensure that their quality and performance meet the production requirements.

1.1 Positive electrode material

Cathode materials are usually composed of lithium metal oxides, such as lithium iron phosphate (LiFePO4) or lithium nickel manganese cobalt oxide (NMC). These materials have high energy density and good cyclic stability.

1.2 Negative electrode material

Negative electrode materials are mainly composed of graphite or other carbon-based materials, which can effectively embed and deembed lithium ions to ensure the charge and discharge efficiency of the battery.

1.3 Diaphragm

Diaphragm is a microporous film used to isolate positive and negative electrodes while allowing lithium ions to pass through. It is usually made of polyethylene or polypropylene.

1.4 Electrolyte

Electrolyte is the medium through which lithium ions move between positive and negative electrodes, usually composed of a mixture of organic solvents and lithium salts.

1.5 Shell material

The housing material needs to have good mechanical strength and chemical stability, and commonly used materials include steel, aluminum alloy or plastic.

2. Battery unit manufacturing

2.1 Positive and negative electrode preparation

First, the positive and negative electrode materials are mixed with the conductive agent and the binder respectively to form a slurry. Then the slurry is coated on a metal foil (usually aluminum foil and copper foil), and after drying, calendering and other processes, a positive and negative electrode sheet is formed.

2.2 Diaphragm Assembly

Insert a diaphragm between the positive and negative electrode plates to ensure safe isolation inside the battery.

2.3 Winding or Stacking

The positive and negative electrode sheets and diaphragms are wound into battery cells or stacked into layered structures in a certain sequence.

2.4 Encapsulation

The coiled or stacked battery cells are placed in the housing, injected with electrolyte, and then sealed to form a battery cell.

3. Battery Assembly

3.1 Single Battery Test

Carry out charge and discharge test on single battery to screen out qualified battery performance.

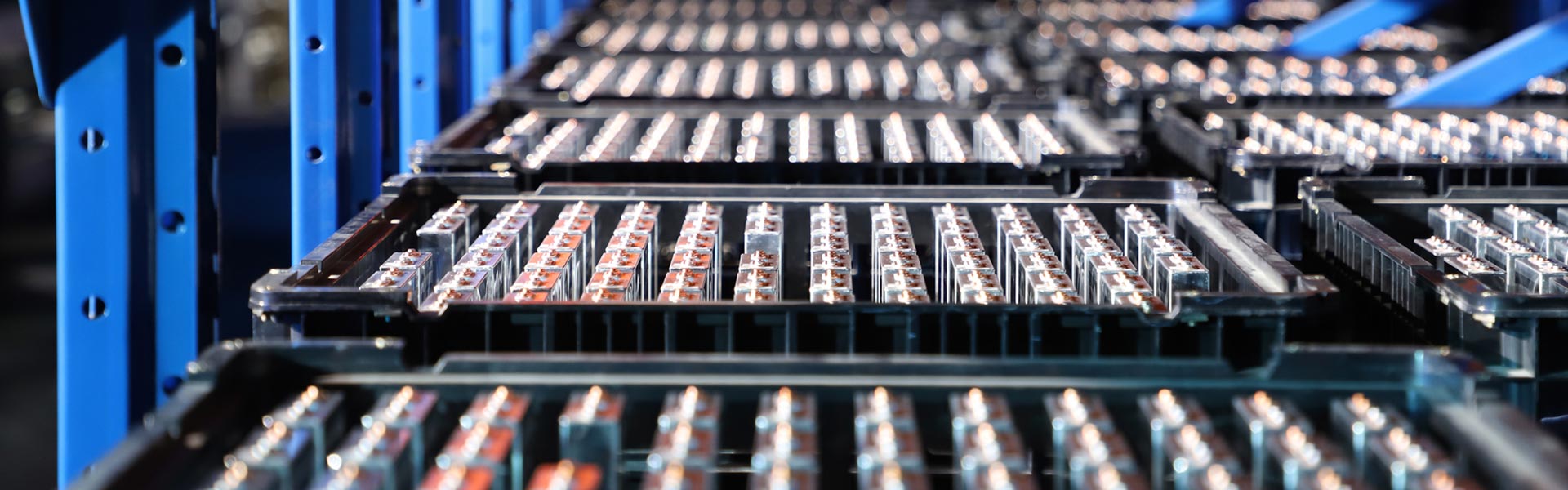

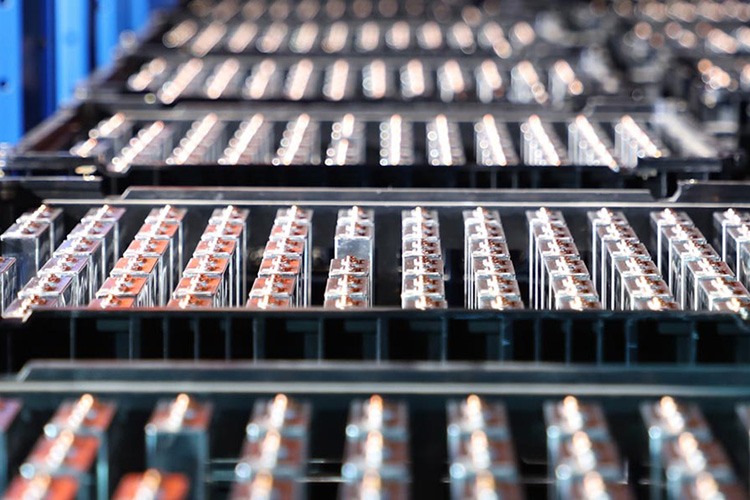

3.2 Battery Module Assembly

Connect multiple individual batteries through bus bars or wires to form a battery module. In this process, it is also necessary to install a protection board to achieve over-charge, over-discharge, short circuit and other protection functions.

3.3 Battery Management System (BMS) Integration

The battery management system is integrated into the battery module to realize real-time monitoring and management of the battery status.

3.4 Battery Pack Test

Conduct a comprehensive test on the assembled battery pack, including performance test, safety test, etc., to ensure the reliability and safety of the battery pack.

4. Finished product inspection and packaging

4.1 Inspection of finished products

Final quality inspection of the finished battery, including appearance inspection, capacity test, cycle life test, etc.

4.2 Packaging

Batteries that pass inspection will be properly packed for transportation and storage. Packaging materials should be shock-proof, waterproof, moisture-proof and other characteristics.

5. Shipping

The rigorously tested AGV/RGV lithium batteries will be boxed and sent to the customer's designated location, ready for use.

Summary: The production of AGV/RGV lithium batteries is a complex and delicate process involving several key steps and technologies. Every link needs to be precisely controlled to ensure the performance and safety of the final product. With the continuous advancement of technology and the growth of market demand, the production process of lithium batteries is also continuously improved to meet the application needs of higher standards.-

About Us

Company Profile History Organizational Honor -

Product Center

Forklift lithium battery Rv lithium battery Wall-mounted lithium battery Golf cart lithium battery -

Solution

Energy storage battery Power battery Server battery -

Know us

News center Contact us -

Contact us

0769-89333805 No. 78, Puxing East Road, Qingxi Town, Dongguan City mg@redwaycn.com

Copyright 2025 Dongguan Liduowei new energy Co., LTDTechnical support:Emore - About Liduo